I guess things have really gone off the rails when you have to make a ‘to do’ list in outline format before you visit the coke plant. But on my 12th visit, that is exactly what I did. It starts innocently enough – you think about all the fun activities that await you the following morning. But then so many of them pinball around your head that you have to write them down. And I do enjoy the outline format because it helps me to keep things straight. One day they will connect a computer to my brain to peek inside and things will be organized this way. I added some notes in parenthesis to clarify the bullet points:

- Coal bunker

- Sweep/shovel out (using the shovel I found last week, I figured I should put it to use somewhere and the bench level of the coal bunker is a mine field filled with junk)

- Battery #1 basement

- Explore properly (I already found two wrenches down there without even trying. What else is down there? I need to actually LOOK)

- Get oven marker (I think a full collapse is imminent before long, and the door way which is already obstructed will become totally filled with rubble, and no one will visit the basement again. There are signs below each oven and that is about as important a piece of history as there is in this place. Of course I will get B25 to prove that I walked the full length of the battery in the pitch darkness to get it)

- Main office

- NE office (I left a number of things behind last week, some of which I stashed and others I just left banging around the room)

- Business cards

- POs

- Blue prints

- More?

- NE office (I left a number of things behind last week, some of which I stashed and others I just left banging around the room)

- BP office

- Move shelf? (I’ve been admiring this functional piece of furniture for months. It is tipped over in the middle of the room but looks intact. I’d like to move it to a more secure area, as well as an area where I can more easily extract it from the property which I may do before long)

Proud to say that over about 5 hours in the plant (the longest I have spent on a single visit) I did get everything done. But before I tell of the day’s events, another outline of all the artifacts I recovered from the site:

- videotapes

- one found at end of cul de sac in coal handling

- one found in main office, NE room 2nd floor

- signs

- oven marker

- fire box locations (found in NE office, which I now know is the assistant division managers office)

- documents

- Chimney inspection (1996)

- found in coal bunker, area manager office

- HKC duct inspection (1997)

- found in asst. division managers office

- “Weak Liquor Stripping Facility Operating Manual” (undated, but documents are marked as Interlake which puts it as pre-1986)

- found in asst. division managers office

- “Best Management Process” (for a potential BP disaster) (1988)

- found in asst. division managers office

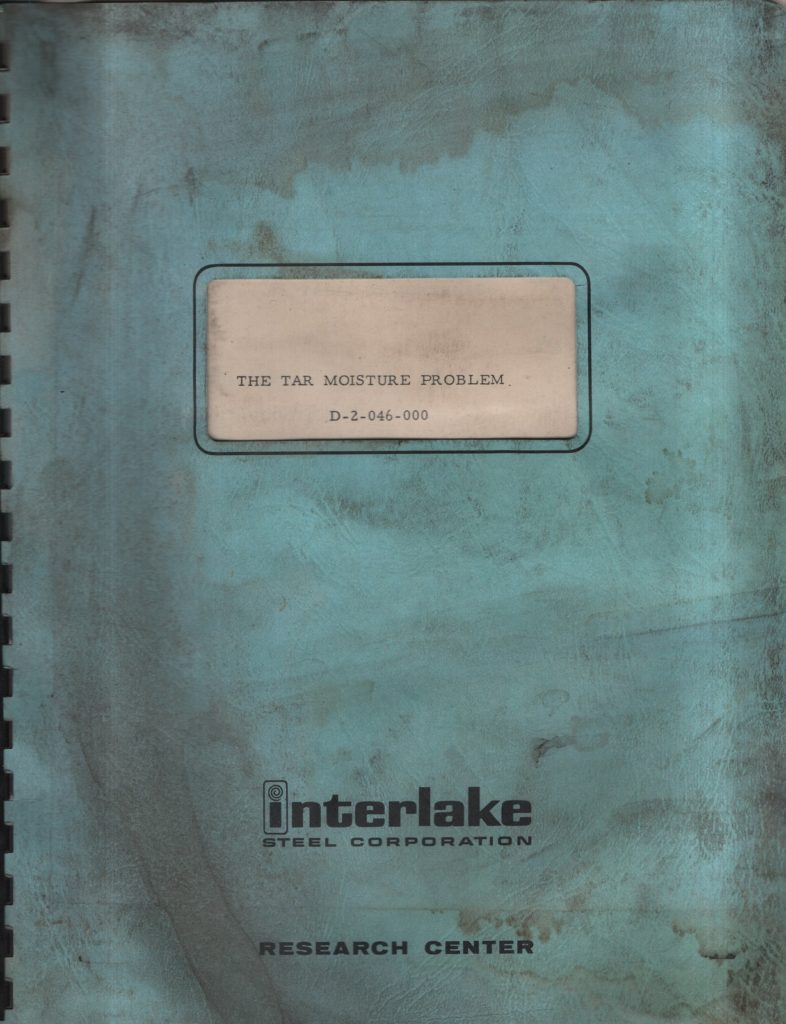

- “The Tar Moisture Problem” (1966)

- found in asst. division managers office

- Purchase orders (2001)

- have 15 total, 4-5 pages each, may not scan them all

- found in asst. division managers office

- Morning reports (1984)

- I have found two formats of morning reports before, this is a third

- These are actually labeled “calculation sheet” but the format is the same, and these also have an Interlake logo at top which adds to the interest

- JSAs

- “Mixing Soup For Lids” (1976)

- “Discing (Sizing) Gooseneck” (1984)

- found both loose in the coal bunker

- Daily Laboratory Reports (1999)

- found in asst. division managers office

- Business cards

- Probably 150 total or more, will touch on them in this post but an entirely new post will have to be devoted to this monumental score

- Chimney inspection (1996)

So onto the day itself and its events. Due to the chilly temps I took the short three mile ride up from Hegewisch and came in through the fence near the quench station. I locked my bike to a small tree as I have been doing, behind the tar tanks near the ovens. Then I walked across the plant to the main office. I walked the plank up to the 2nd floor and got back to work in the NE office. I was relieved to see that the things I had stashed had not been disturbed.

The ovens area manager’s office in the coal bunker was for a long time the biggest trove of documents I had found but this might have it beat. The SE office yielded some great documents but the room is pretty clear. The NE office however is a pigsty and I can only think the occupant was a bit of a hoarder or in his own defense, perhaps things got shoved in there when the plant closed.

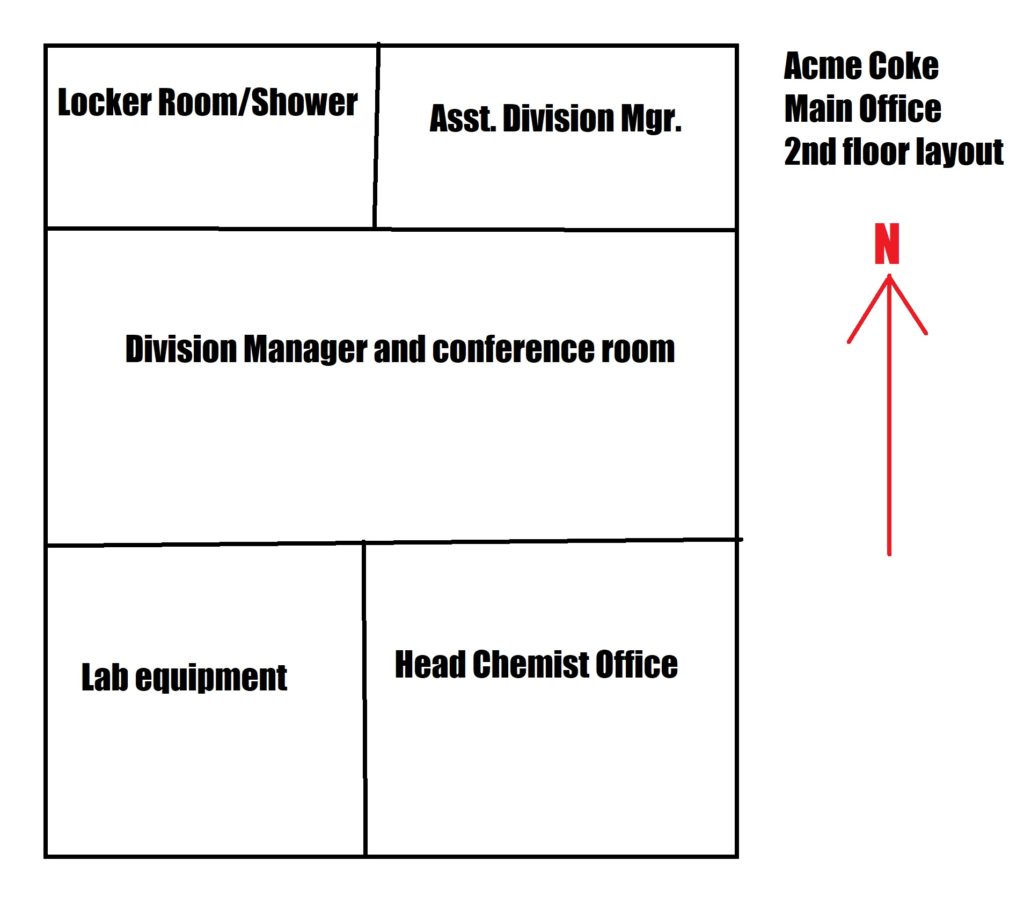

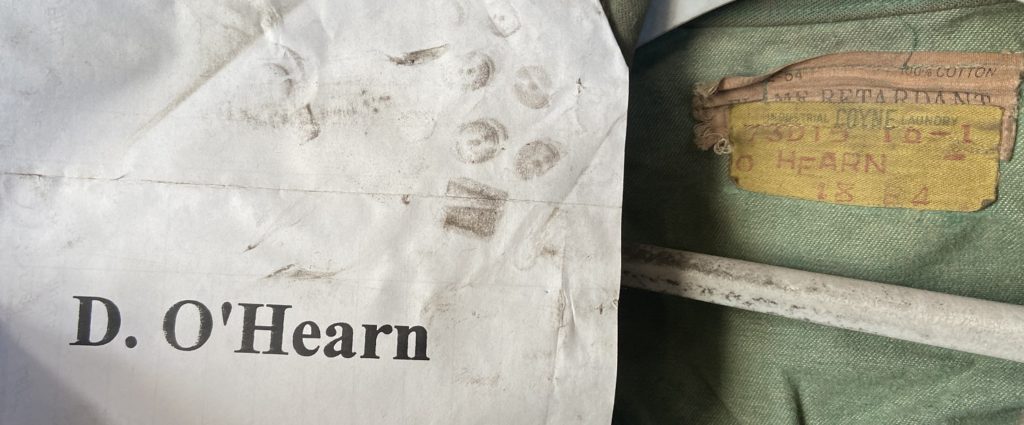

I was able to discern the owner of the SE office (Dr. Charles Lin) through the documents I found there. I have since figured out the owner of the NE office (Dick O’ Hearn). With that knowledge and some help from Doug, I present this layout of the 2nd floor:

There has to be 8-10″ deep of documents at any point in the NE office. Last week I found that some of the disintegrating wood paneling on the east wall had fallen over and trapped plenty of documents beneath it. This is where I located the binder of business cards last week. So that taught me a lesson that unfortunately I’d have to dig deep to really try and find some good stuff. Of course the deeper you dig, you generate a huge cloud of dirt and dust. I had a gaiter on just to protect my neck from the cold so I put it on, it looked a real mess by the time I got home. But I reassure myself that it is a noble mission, at whatever cost, because there are things of great importance in that room and everywhere you look.

I was pretty quickly confirming who’s office this was and after reading nearly 1000 documents I knew the chain of command pretty well. If this welder’s coat was in better shape I would have taken it home and washed it. But alas Mr. O’ Hearn was clearly quite a bit smaller that myself.

Found two exotic things (in glass containers!) pretty quickly but they turned out to be pretty innocuous and I left them behind.

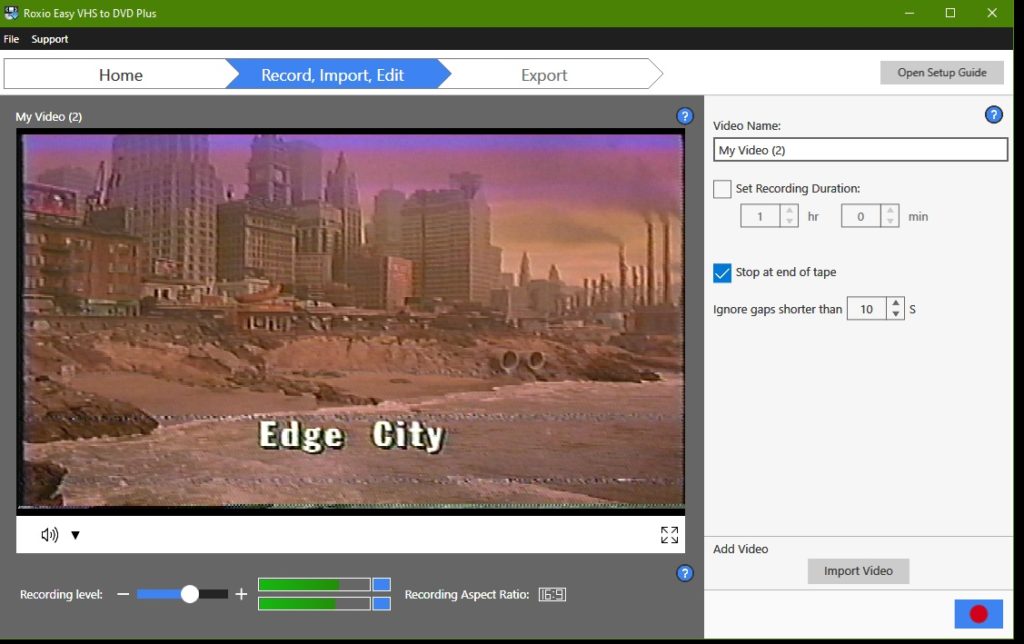

Shortly after that I found a videotape. I was certain this wouldn’t be another bootleg movie considering where I found it (and it was well buried). The paper sleeve was shot but it did it’s job because the tape itself was immaculate. I did a google search right away to look up the name on the sticker. This Minooka based contractor does some seriously dangerous work, diving underwater in industrial settings.

If you are wondering why the quality is so poor, don’t blame me or even the storage of the tape itself. This is clearly shot on some kind of underwater camera and I’m pretty sure that GoPro wasn’t around yet! Unfortunately it does not look like this was shot at Acme. The only place I can possibly think that they would hire such an outfit for would be to get into the bottom of the quench sump. Occasionally larger pieces of coke would make it past the screens and clog the pumps or even make it all the way back up to the sprays in the quench station. So like the Actin Inc video I found, I’m guessing this was more or less a promotional video to show what they could do. At the end of the video you can see some kind of large structure as the diver surfaces but it is not familiar to me. The most interesting/haunting part of the video is the diver’s voice that answers ‘alright’ again and again to the commands coming from above.

The business cards I found are pretty amazing. I have already started doing a deep dive on some of the people and companies on them and this will have to be covered in a separate, much longer post. Some of the vendors I recognize from my research into the plant but others I don’t know. There are more than a few which are local to Chicago, or even more specifically to the south and southeast sides of the city. Interesting to see the vendors that set up shop in the area with the steel industry that once thrived there. There are quite a few cards from other steel companies and even coke plants. Very interesting to see that colleagues put competition aside to work together on some level though I’m guessing that money helps that goodwill along quite a bit. Unfortunately due to it’s age and the frigid weather, when I opened it, the cover cracked off. Not a huge deal since I already have a good Acme binder at home, and there is no shortage of spares in this office. Had I let it ‘thaw’ in room temp it might have been OK. Too bad since it was in mint condition otherwise.

I found four separate reports in the office as well that I took back with me. All of them (described in the outline at the beginning of this post) are bound either with spirals or other fasteners. Interesting to think about how big such an industry would have been before PDFs. If you wanted it to look professional, you paid to get a box of these things printed to share with your boss or your co-workers. All of these are now available in the Document Archive.

“The Tar Moisture Problem” caught my eye immediately as it has a huge Interlake logo on the cover and when I see things that I know are that old, I always have a look. This one is from the mid-60s so that surpasses my guess and adds to the excitement. It is the shortest of the four but a fine read about a problem that every BP plant in the world has dealt with, I am sure. It also includes two additional memos which were stuffed in (one from 1965) on the subject.

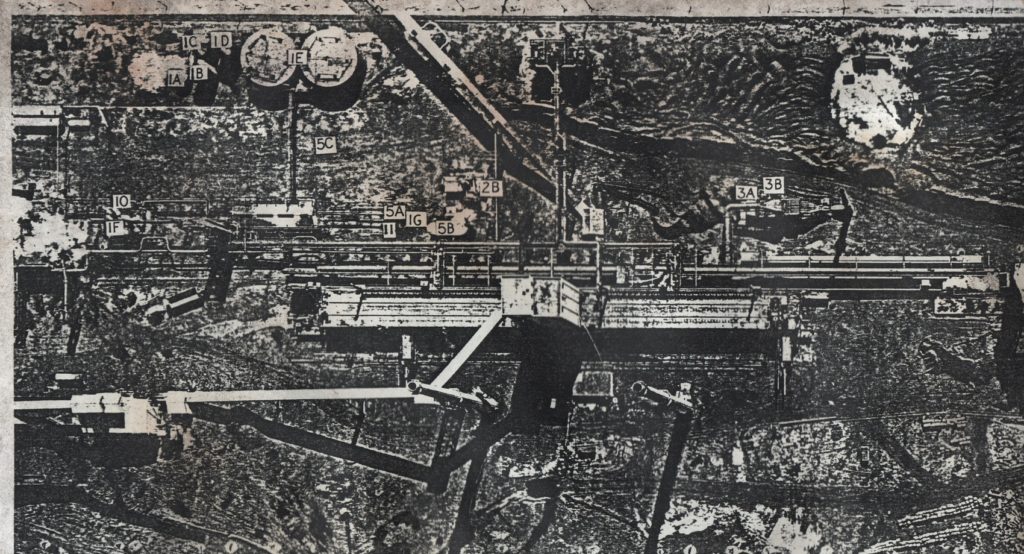

The “Best Management Plan” is the type of dull boilerplate I always toss back into the heap. But through some stroke of luck, as I flipped through it I saw some maps! I didn’t need to look any further before it got stuffed in my bag.

Turns out to be a pretty interesting read. A better title would have been ‘What to do when the BP plant has a major environmental disaster’. I laughed out loud at page 8 which covers how to deal with the EPA. Of course it mentions not to answer questions unless you have to but specifically states “A friendly, courteous, and professional attitude should be maintained with agency representatives”. I’d say so! Curse the guy out and they will shut the plant down! The full report was over 50 pages but half of that was the aforementioned boilerplate. Ironically, this is the only of the four that had a damaged binding. So I carefully extracted the stack and went though it page by page to discard the boring bits. The maps aren’t the highest resolution but still useful. And the entire second half of the report covers the full inventory of tanks and vessels on the property, and where they are and what they contain. All of that has been salvaged and will make a great addition to the document archive. The more I dig into this the more interesting it gets. It even covers retired vessels (some of which were built prior to 1920!). I think the public and the federal government had a general consensus that a coke plant is a poisonous, awful place. I’m not saying it is a ‘green’ operation and without arguing that it was very necessary a document like this tells another tale. This is an internal document but it is very impressive to see a detailed discussion about all the safe guards already in place and bullet points about what to do in case of a failure. This document is a lesson in archeology – you need to look close and not “judge a book by it’s cover” when trying to determine its historic worth.

I have been getting more and more interested in the BP process for a while, but especially after going through the lidman training. So the “Weak Ammonia Liquor Stripping Facility Operating Manual” is of special interest to me. It looks to be from the mid-80s but is in perfect condition. I may not scan the whole thing but at the end it has some what I call ‘Mad Magazine’ style folded prints (folded in thirds like the “Fold-In” at the back of their issues) which I may try to scan.

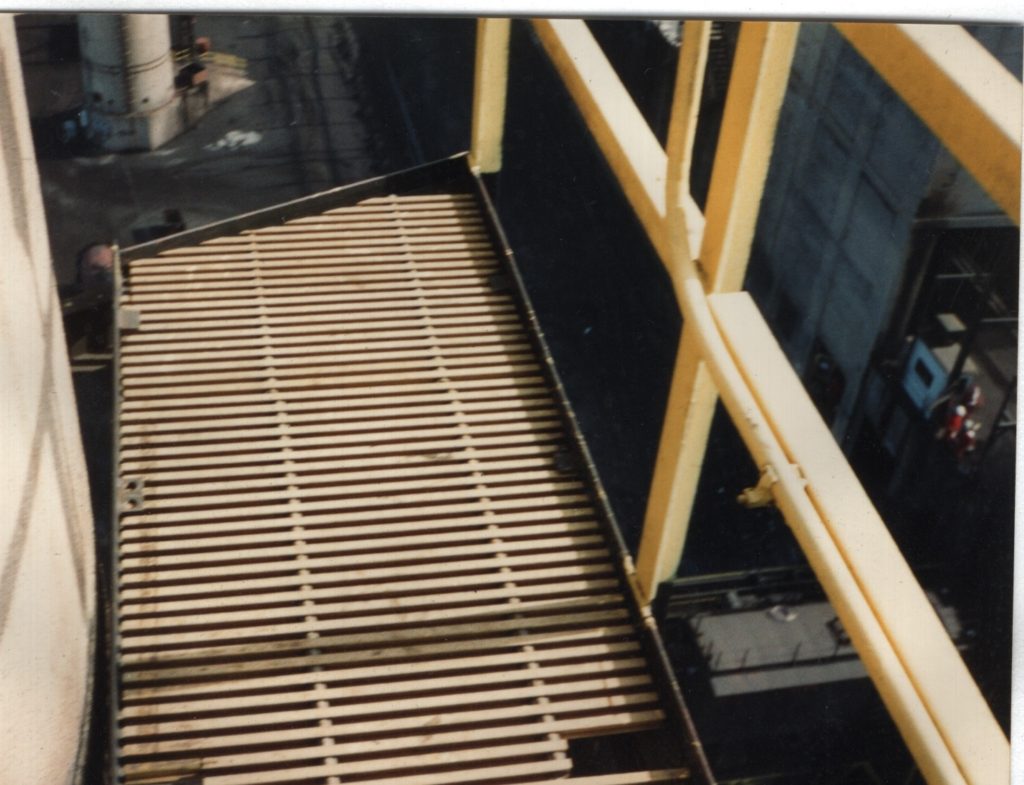

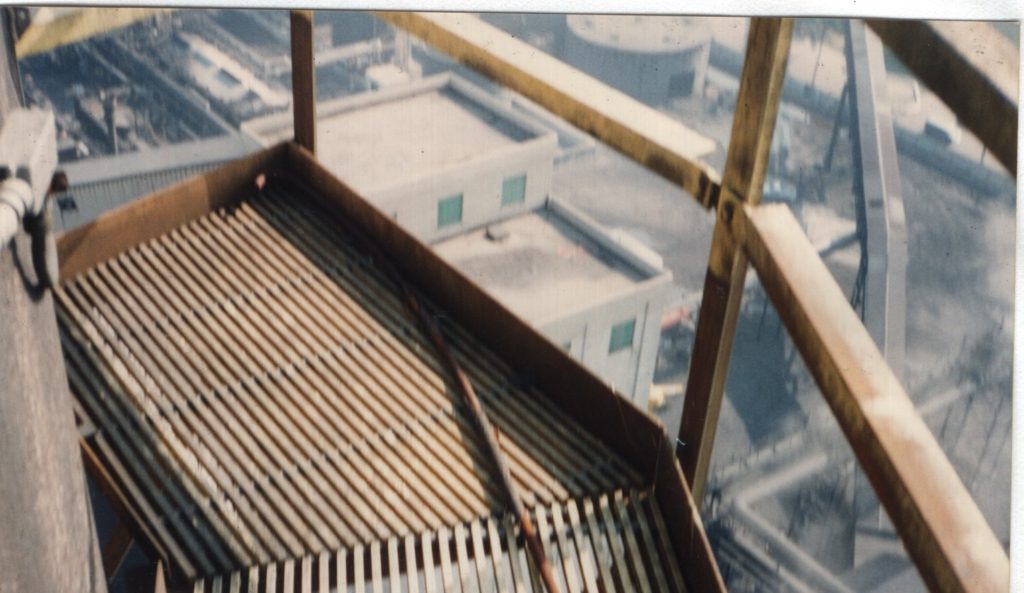

The HKC duct inspection report is a good one. It isn’t very long but contains two neatly folded (impeccable condition) blue prints tucked away in plastic sleeves. The inspection was done by Orbital Engineering, and I recognized the paper stock and ink color for the prints from a couple I found in the coal bunker months ago. Stupidly, I left this in the mess on the floor last week. I remembered that the binding was red but that is like a needle in a hay stack in that mess. Thank god I found it!

Had to go to Doug for a clarification on where and what the HKC duct was: “HKC was German company Hartung Kuhn Co. They designed this push emission capture system. There was a building 50′ east of the center of the wharf housing a huge motor and fan that was connected by a huge solid pipe. This duct work ran overhead (east-west) to the center of the batteries. It was open at the top where it branched off the duct from the building to running parallel along each battery north and south. This system contained a movable capture hood (conveyor belt driven) which ran on rails above the door machine just east (engineered so the belt itself covered and sealed the openings where the hood was not in capture position). The door machine operator would position the hood, the quench car operator would operate a pin that would hold position of the hood over the car. The hood was radio controlled and would follow the quench car to the end of #2 battery, detach from following the car and wait for the door machine operator to call it back to the next push.”

In perhaps a summation of Doug’s description (and one of the greatest run on sentences ever): “An improved duct system is provided for collecting gases from the coke side of a battery of coke-oven chambers with vertical flues in which a coke guide is mounted for movement along the ovens on rails, in which the coke transport car is mounted for movement on rails along the ovens adjacent the coke guide, and in which a stationary main collection duct with a belt covered slot is provided adjacent the transport car rails”

Continued digging yielded a small box which was still sealed. This would have to be good. I savagely tore at it and inside found quite a score! It needs no introduction.

I found a handful of other less exciting documents then after over an hour up there I decided to move over to ovens and get down into the battery basement one more time. I made my way down to B25 on the pusher side and saw that while all four bolts on the oven marker were quite rusted, they refused to give. I was making more progress destroying the concrete than breaking the bolts. I considered buying a sharp chisel for this purpose last week and decided against it. I cursed my poor decision and determined that I was not meant to have the sign. So I started roaming around, looking for more tools or other artifacts. I was on the coke side headed back when I noticed a sign was missing. Then I saw that the next one (B16) had only a single rusty bolt holding it in place. I started with my screwdriver then just bashed at the head of the bolt with my hammer and it gave out pretty quickly. I noticed that at least two others in the vicinity are gone but they weren’t on the floor. No doubt captured by other archeologists, perhaps years ago. And now they all hang together, as they should be, on my wall for constant appreciation like a new pet. My thorough search of the entire area yielded nothing additional. Probably my last visit to this scary and dark place.

From here I went back north to visit the BP office. I had my eye on a piece of furniture clearly made by an employee. I can only call the style ‘industrial’ and I know it well, because my home and work office are filled with similar structures I have put together. I must hand it to the builder of this one however as it’s attention to detail surpasses my own. I have no place for it at home and I am struggling to calculate a way to make room for it in my office. I am yet undecided but I did make the trek to haul it across the plant to a new (undisclosed) location. It wasn’t easy but it was satisfying work.

When I got it in place, I then went a shorter distance to snag a similar piece which was laying in the rubble of battery #2. It is not nearly as elaborate and also has some damage, but something drove me to rescue it as well. I cleared the area here and now the twins can revel in their new home. The nice thing is that now I have a good place to temporarily store my finds on a long day so I don’t have to continue to carry them around. The shovel I found last week lies in way nearby.

From there I decided to put my new shovel to use. I figured I’d shovel some of the rubble and refuse out of the first two rooms on the bench level of the north side of the coal bunker. Unfortunately, the handle did snap – sleeping rough for twenty Chicago winters will do that – but I made some progress. I don’t have a very good answer of why I’d undertake such a task. So I’ll just file this one under ‘fun’ and leave it up to the viewer to puzzle over how that is possible. Different strokes!

I ducked back into the area managers office to dig through what is left in there. I have gone through it enough times that I don’t think there is much left but those are famous last words of the poor historian who leaves the most important things behind. And I found a hell of a document!

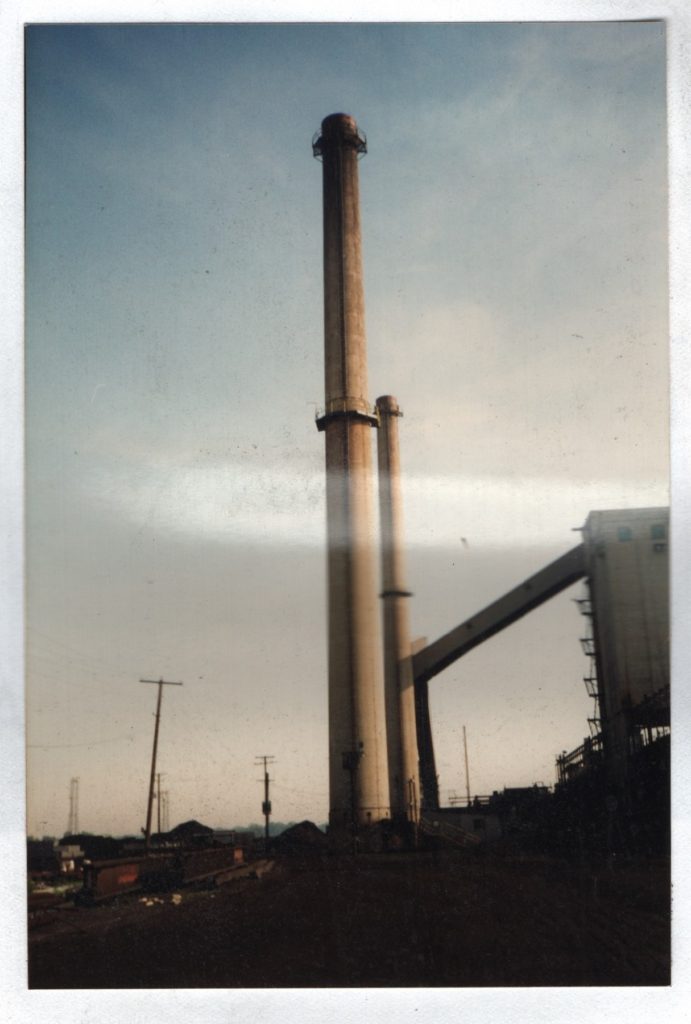

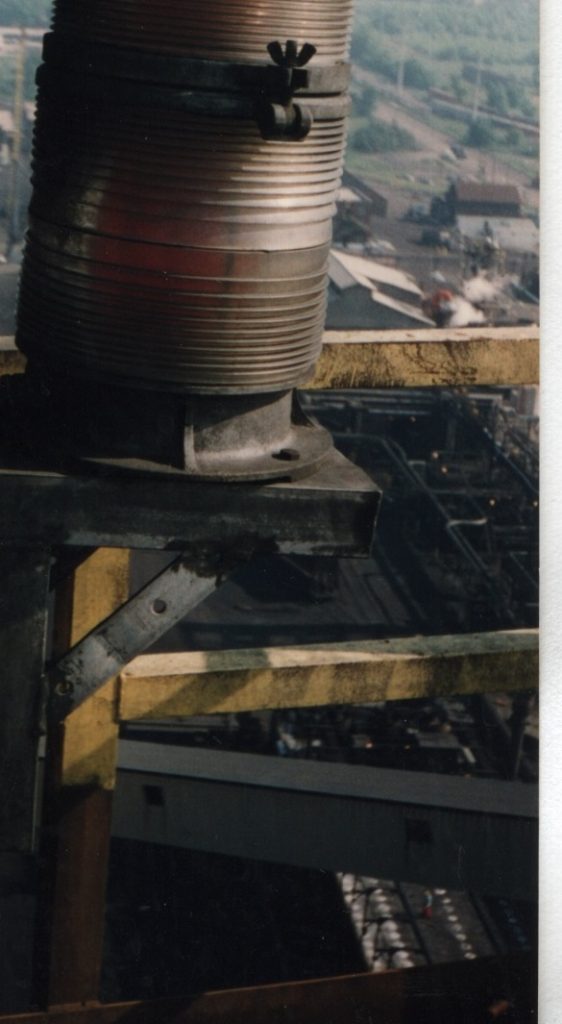

I wish I had a copy of the invoice or purchase order to see what it costs to have someone climb up the battery #2 underfire stack. Hey, its only 250′! Maybe that guy and the underwater diver from Lindahl have beers at the end of a long day. If not, they should. Of course at least back then, then ladder had a cage surrounding it. But I don’t care how many times you could tie me off to something secure, I literally feel queasy to even imagine it, even going up 100’….no thanks.

The funny thing about this elaborate report is that all of the findings are based on visual inspections. I have looked at these chimneys more than once and wondered how when everything else around has fallen, how is it that they are still standing? Well I wouldn’t ask the guy that looked at this one because his only deductions are that things are ‘safe and sound’ or ‘solid and sound’. One of the biggest findings is that one of the aviation lights wasn’t working. What an amazing deduction!

But before I go on too long let me get to the best part. There are 41 full color photos glued into the pages! And looks like none are missing. Most aren’t that interesting as they are so close up but the very first photo is such a gem. It has to rank with the greatest discoveries I have made during the hours I have spent searching.

Notice the conveyors are still intact feeing the charging bins at the top of the coal bunker. Looks like a wonderful sunny morning in mid July to me! I can say that despite the hundreds of photos of Acme pre and post shutdown, this is one of a kind. The best part is that it the report was sitting out on top of a heap when I walked in and it immediately caught my eye. Seems like some of the best finds I’ve had were in similar conditions. Divine intervention I am sure.

After thinking about it, I decided to pull everything out of the binding. This allowed me to scan everything properly. This pained me a bit as the entire report was in such good shape I would consider adding the entire thing to my personal archive. In the end I decided that not being able to scan it well was enough of a reason to tear the thing open. I saved the best physical pictures for my person archives. They are double stick taped onto the pages with some seriously good tape. I couldn’t peel them off so I just used a scissors and trimmed them out of the page with the paper still attached to the back. They will go into an envelope. The first page with the photo above I left as is and laminated the whole page, photo and all.

After I got everything scanned I went back in and saved crops of any photos that show any tiny view of the ground below. Some have some decent snippets of coal handling or part of BP. Here they are.

At this point in the trip I can honestly say I was getting exhausted. I was pretty hungry and was just about done but I couldn’t bring myself to walk away. So I just started wandering as I often do and I made it back to the coal handling area. I started walking south down the cul de sac from the locker rooms. I never knew it was a cul de sac until I saw a map since the west half is totally overgrown with foliage. And I found something very interesting.

If it isn’t evident in the video, the tunnel seems to lead east/west and is filled with water. I can only hope it dries out in the spring and I can get down there. I have never walked back here before. Why? Because there is ‘nothing there’. But leave no stone unturned. Once again, leave it to Doug for an explanation: “There were two underground hoppers. This is the entrance to access the area underground where the hoppers could be fed onto a belt that ran underground to the transfer tower and onto another conveyor that ran to the pulverizer. If you stood on top of this concrete structure and faced east the two ground hoppers would be right in front of you. Just east of the ground hoppers were two overhead bins (stock out hoppers) that were fed from the dumper. Those load out hoppers had hydraulic gates that the Euclid operator would open when he parked underneath to load up. The E-man worked from this area and coordinated with the Euclid operator when the mixer bin man signaled the next coal that was needed to fill one of the four mixer bins in the mixer building. “

And once again I found a smashed up videotape. Get ready to be disappointed!

This has to be the longest site visit post I’ve done, and I know it was the longest visit. It was a quiet day, with no sign of anyone and the hours flew by. I was exhausted that evening and even Sunday. Can’t wait to get back!