One thing that has always intrigued me is the history of plant, related to the various mergers and spinoffs that have changed the name of the coke plant since it opened in the early 1900s.

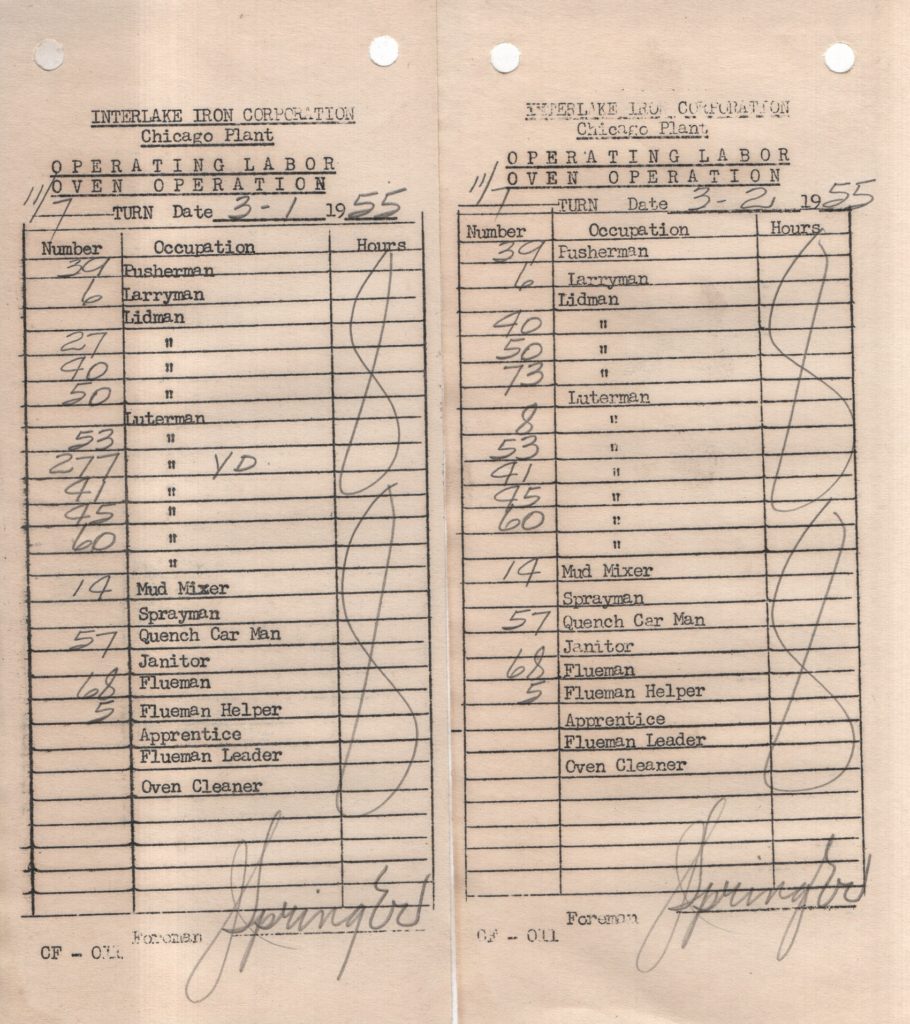

The oldest documents I have found that show ‘Interlake’ as a name are from the mid 50s, I have a few examples:

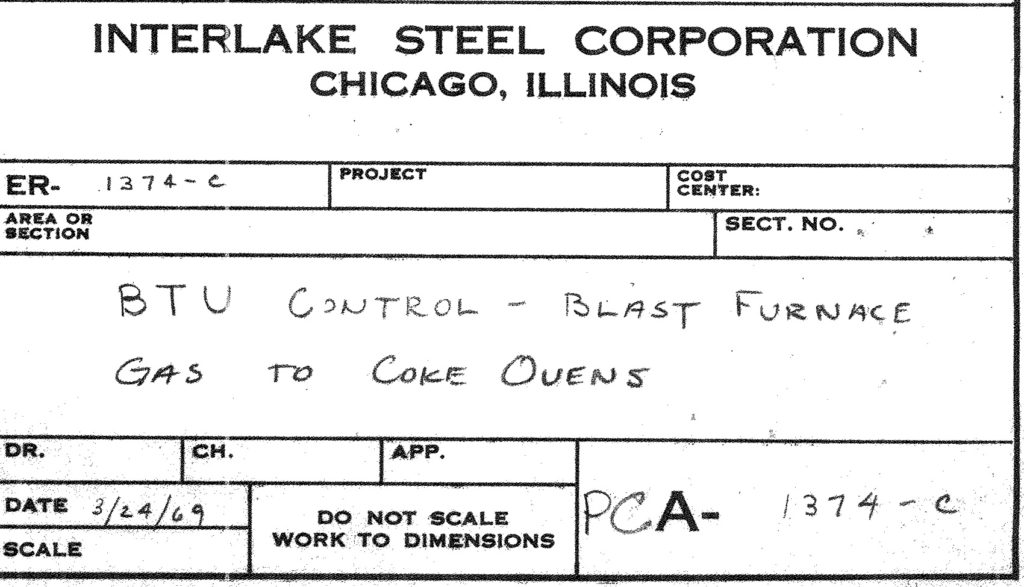

The designation between ‘Interlake Iron’ and ‘Interlake Steel’ is important. Before the merger with Acme in 1964, Interlake must have only owned the coke plant and blast furnace. This allowed them to make pig iron, but they had no mill to finish the process. Once the Perry Ave facility became part of the Interlake corporation, they buried the Acme name and Interlake Steel was born.

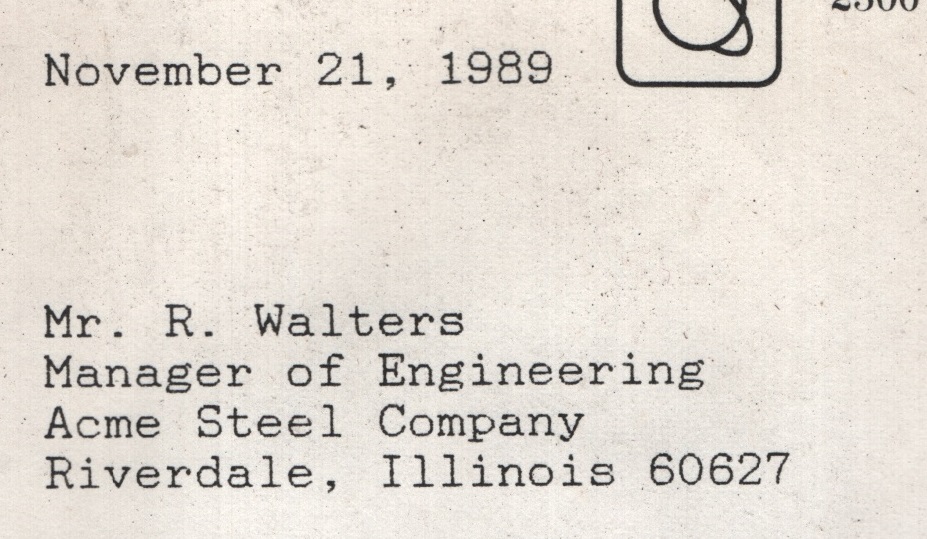

Then, the company spun the entire operation off and the Acme name was reborn in 1986, and that takes us to the plant’s closing in 2001.

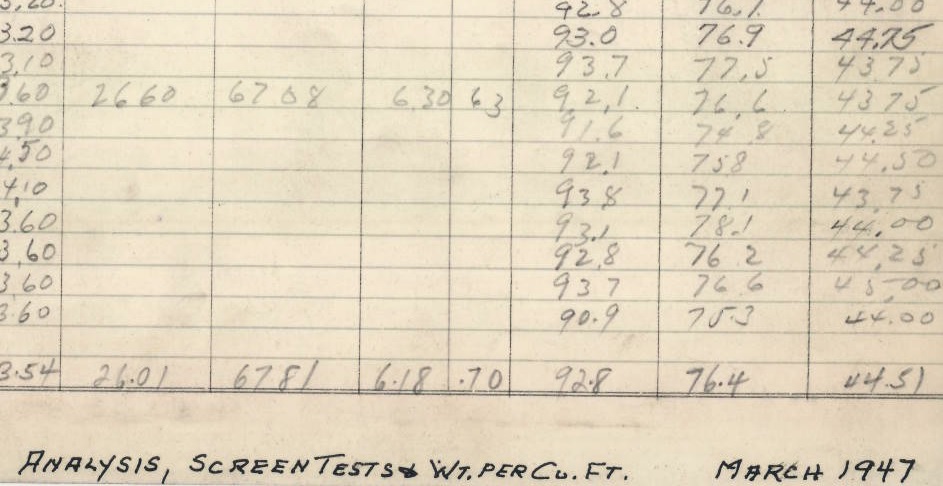

But what about the early years? How long prior to 1950 was the plant operated by Interlake? I was fairly sure there had to be at least one previous owner. I have found pre-1950 documents but they were unfortunately unlabeled.

First up were these late 1940s documents on coal quality which were rescued from the 3rd floor main office archive. This is a crop – there is no company letterhead unfortunately.

I was almost shaking when I saw the date on this print – 1926! My holy grail but alas, no company name ANYWHERE on the massive drawing.

Then recently, I came across this tidbit in a 1996 edition of the Chicago Tribune. At least I had my answer.

So it turns out that my 1926 print is actually the only pre-Interlake item I own. “Byproducts Coke Corp” – interesting. I can only hope that I find something before long. Something else that I have often wondered about from the early era is what kind of battery arrangement the plant had before the Wilputte batteries were built in the late 1950s. As demonstrated, I do have a handful of documents from that time, but nothing that helps me determine the make and model. Wilputte didn’t patent their underfire design until 1941 so I knew it would have to be one of the other big players of the time. It is very probable that the batteries which underwent demolition to make room for the Wilputte’s were built in 1905 when the plant opened. But what would they be? ‘Modern Coking Practice’ from 1910 (available in the Resources section) has the answer – but it is a multiple choice question.

Chapter VI (“Coke Ovens”) is a great snapshot of the coking industry just after the turn of the century. The contemporary types outlined there are:

- Simon Carves

- Semet-Solvay

- Huessner

- Otto-Hoffmann/Otto-Hilgenstock

- Koppers

Certainly Koppers I am familiar with – they continued to build and support batteries until the Acme shut down. I assumed I’d never know the answer to this question until and unless – as I have said many times before – I can retrieve some fuel for my time machine! And that keeps me awake at night.

Last night in a half drunk moment of exhaustion as I awaited the delivery of a pizza around midnight, I was watching TV and doing some reading on my phone about – what else – coking. I had visited once before and as down the rabbit hole I went, I returned to an excellent website that I highly recommend. There, he shared an ancient drawing of the plant from 1917, if I am reading correctly.

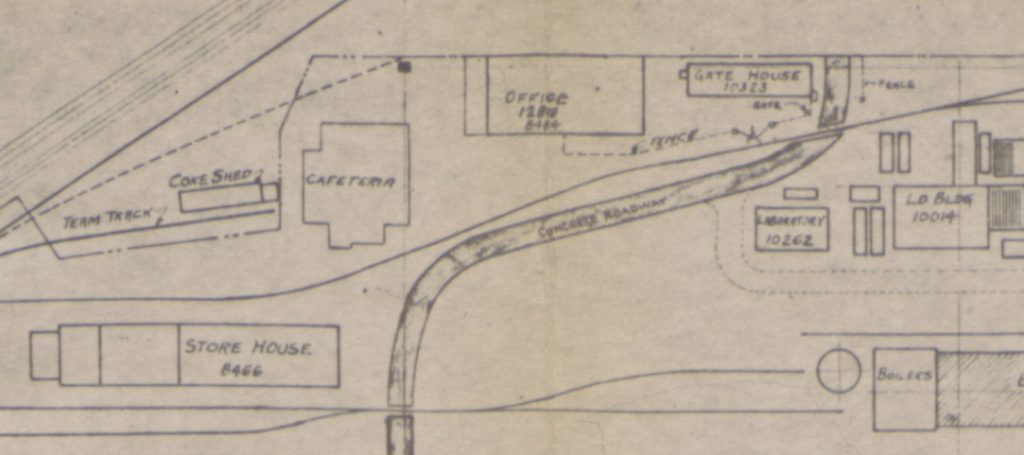

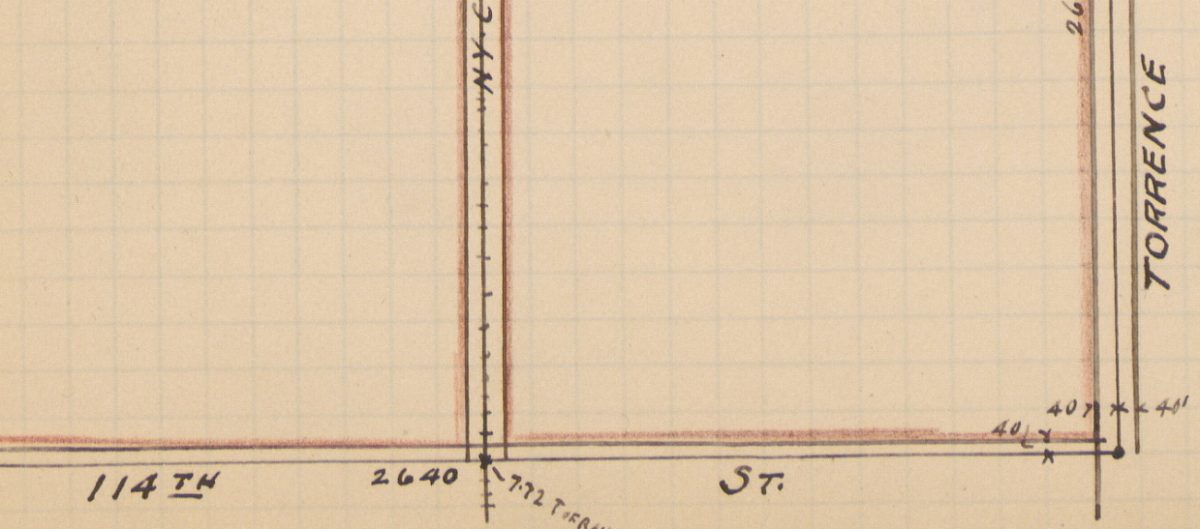

And from where did this amazing print come from? Cornell University? What would they care about a coke plant in Chicago? Because Cornell’s home in upstate New York is also the home of a historic company, today known as Solvay Process Company. Sound familiar? And at last the question I long pondered was answered. Semet-Solvay started building these ovens in the late 1800s, so the Chicago coke plant must have been a big deal. Especially when we have a closer look at the print and examine the layout of the property and the placement of the oven batteries.

When Acme closed in 2001, they had two Wilputte batteries with 50 ovens each, for 100 total. And in the 50s, before the Wilputtes were built? How about 280 ovens! That’s right – they had not two batteries but seven!

The batteries appear to have 40 ovens each. I am not clear how one coal bunker could support four batteries, but I am not clear on how charging worked in those days (I am fairly sure that larry cars were not used). More strange is that battery #5 is nowhere to be found, leaving an odd number to be supplied in the eastern arrangement.

I can’t imagine how long the plant had to be shut down to demolish all of these batteries, much less to build two entirely new ones. But it makes more sense that some of the Solvay batteries were left online while the Wilputtes were being constructed. I know the both of the Wilputtes were online by 1957, but I also have Wilputte design prints as far back as 1950. However, the early ones are for the by-product plant, not oven batteries. So perhaps this is where Wilputte got their foot in the door with Interlake, to pave the way for the purchase of two new batteries.

So this must have been a very long process of planning then eventually demolishing Solvay batteries #1-4. I can’t imagine how inefficient those old batteries must have been, that they would go from 280 ovens to 100 in good conscience. Either the oven chambers were substantially smaller or the coking quality was inferior enough that the Wilputtes out performed them. It is also very possible that some of the seven Solvays were already dead by the 50s and demolished or RIPd (retired in place), in a slower process over a number of years (or decades?).

So in summation:

- 1905-1929: By-Products Coke Corp.

- 1929-1964: Interlake Iron

- 1964-1986: Interlake Steel

- 1986-2001: Acme Steel

A glance at the gate house area shows that not much has changed since 1917! The cafeteria and store house placement are the same as they are this morning. The driveway hasn’t moved, as I know now trucks traversed that path for 96 years. I’ll remember that the next time I walk or bike along it. The light oil structures are long gone but those too never moved even as they must have been rebuilt many times over the years. Hard to accept that battery #6 was just a few hundred feet from the gate house.

Dennis site again needs to be recognized – I see he has collaborated with Rod Sellers more than once. I have reached out to Rod before but not heard back and I hope Dennis comes across this post. I thank him for his commitment to history, his excellent website and the content which led to this post today. Check out his site today!

11 replies on “And before Interlake…”

stocks owned by my father

He owned Interlake Iron stock?

My father was employed as a sales representative for Interlake Steel Corp., located in their Indianapolis office. He worked in the steel mills around Gary to pay for college. He did steel spark testing to determine the strength of steel pieces in the 1950’s. (Few people had this knowledge and skill at the time.) I have a round medium size ashtray with the inscription “interlake steel corporation” in the middle, and ACME STEEL to the right side, and at the top “America’s newest integrated steel producer”. I came across your article while researching the ashtray.

thank you so much for commenting! i assume you found it already – but it sounds like i have the same ashtray! i bought it on ebay a couple years ago. it is truly a historically relevant item because it is notating the merger between interlake and acme. ill have to read about steel spark testing. again, thanks so much for commenting!

check out the link above!

If you had any time sheets or anything with my father’s name on it it would be great. He worked for Interlake and then acme steel. He was forced to retire in 2001.

what is your dads name?

I need a little help please. Worked at Interlake Steel in 1953-1995. I need information about my pension. Can you help?

Yes, go to pbgc.gov or call 1-800-400-7242. They should be able to help you there.

Thank you Linda!

You’re welcome. My father worked there all through the 70s and 80s and I had to settle his affairs after his passing, so that’s why I am able to offer this info. This site is really great, thank you so much. It gives me a greater understanding as an adult about how my Dad put food on the table!

Did he work at the coke plant? Or the furnace plant, or Riverdale?