I began rescuing documents from the plant in the summer of 2020, on my third or fourth visit. Initially, I simply found some blowing in the wind, scattered on the ground. Later, I began to actively search. Eventually, I found a large stash and began bringing them back in bulk. The product of this archelogy are the documents I have scanned below – they are the history of the plant and the company itself. There are approximately 2600 pages available below.

…once you put it out, it exists. Once it’s out in the world, it’s out in the world. That can get copied, it can get analyzed, it can get critiqued. But if it’s just sitting on a shelf, it only exists in a theoretical way. It does not exist.

Michael Cuscuna

Some PDFs have been compressed slightly to prevent very large file sizes. I do have high resolution PDFs and/or JPGs for every page here (available upon request). I do retain the originals for a small number of historically important documents in my personal library (seen in the photo above).

- Most scans were done at 300 dpi on an Epson V19 or a Canon LIDE 300 (both flatbeds).

- Bulk scans (lower quality, usually only for text) are done on an HP LaserJet M3035 sheet fed scanner at 96 dpi.

- Scanning for large prints is out sourced to Accurate Repro of Naperville IL.

Training/safety documents

Excellent guide to responsibilities for lidmen, possibly the most detailed text I have located so far on any topic.

Detailed outlines for lidman responsibilities

Detailed outline for larry car operator

Excellent training material – 14 pages of drawings and diagrams.

Approx. 75 page binder – excellent training course

Job safety analysis documents outlining tasks and their inherent dangers for the ovens department.

Accounting

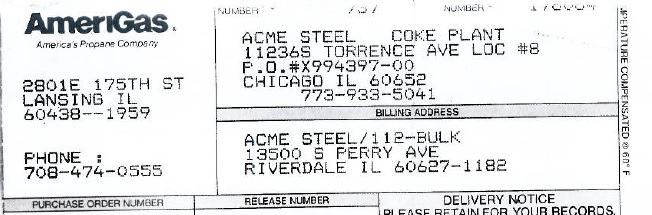

Invoices for liquid propane.

Travel and corporate credit card policy

Summary and signed authorizations for projects to repair/improve the plant.

List of account numbers and expense codes for various coke plant cost classifications

More signed authorizations for projects to repair/improve the plant.

Monthly analysis of materials processed and expenditures

POs and requisitions

Purchase orders

1995 purchase order cancelation for a load of coal, accompanied with back-and-forth between Acme and the supplier

Reports

All-inclusive reports for all areas (ovens, BP and coal), distributed daily.

Older batch of morning reports with hand written format.

Hand written and on Interlake letterhead

1984 specification to build a new lunchroom in the old powerhouse building

Yet another variant of the ‘morning reports’

Ovens and BP reports from 1956.

Daily time sheets which also used the back of the pages as a log for daily tasks

A taste of hand written reports from the coke plant’s resident petrographer, Dr. Lin

Ovens

1959 correspondence between the coke plant and Interlake HQ in Cleveland regarding expansion of the new (less than three years old at that time) Wilputte batteries

Proposal and report on new system

Detailed problem analysis and solutions for various department positions and common situations

Correspondence from coal company on possible causes

Proposal to complete oven chamber repairs

Report (includes 5 prints) on improvements to larry car loading/charging

Thorough text outlining the basis of responsibilities in the ovens department

Collaborative effort with furnace plant to cut off and purge main COG line for maintenance purposes

Assorted correspondence and specs to install a COG detector with panels and meters around the ovens department.

Various internal memos regarding commissioning of new quench car and associated start up hiccups

1991 quotation to test some new oven doors from a Japanese supplier

1994 analysis of flue temperatures related to coking time/pushes per day

Detailed guide on NESHAP compliance

Documenting oven charge timing and visual inspection of doors

The plant’s short lived experiment in foundry coke was coming to an end. Less than a year later, the entire plant would come to an end as well.

A brief memo and related spreadsheets covering costs of vendor ceramic welding for oven batteries

Logs used to keep track of maintenance procedures for individual ovens

Pushing schedules and oven inspection worksheets

Detailed temperature data throughout the battery

Documentation of ovens that refused to push easily and needed to be dug out

Three different formats of the same report, mostly filled out by lidmen.

Operator checklist for door machine

Operator checklist for pusher

Operator checklist for quench car

Oven emission checklists, measuring leakage from the battery lids and doors

Internal communication regarding EPA compliance on battery components

Inspections

Aerial inspection using thermographic camera to read heat signatures of various parts of plant, to determine amount of carbon buildup

A closer look at the one mile+ conveyor belt that connected the coke plant to the furnace plant

2000 report by Enspect

Internal 1977 thermographic inspection

Inspection and repair proposal for the two battery underfire stacks

Internal reports to inspect gas bleeder stack

1994 inspection by Wilputte

Inspection by Orbital Engineering on the supporting structure of the bench between battery #1 and the coal bunker

1983 OSHA mandated inspection of all cranes in maintenance shop

Follow up to oven walls inspection months prior

Internal report on failure of COG line at furnace plant (with photos)

Proposal for end flue replacement

1994 Report from Wilputte, investigating a nasty expanding coal blend

1997 Inspection of emission duct and emergency repair authorization for exhaust fan by Orbital Engineering

2000 inspection of the then 50 year old ammonia tank by Enspect Inc

1989 inspection by Orbital Engineering

Internal report to determine condition of 36″ mainline leading to furnace plant

Internal report – follow up to damage of unknown origin to COG main line

BP Documents

Instructions on the careful procedure to restart an inactive battery.

Detailed instructions for many BP areas

NESHAP compliance for tar tanks and other BP plant facilities

Collaboration with nearby steel plant, working with water reclamation district to illustrate improvements in toxins released to waterway

1959 correspondence on troublesome component of ammonia sulfate plant

Proposal for repair

Specs for replacement of important BP vessels

An experiment on using a new solvent to clean BP components

Data taken at various points in BP plant. These go into the last month the plant was in operation (November 2001)

Purchase requisitions to paint and recondition ammonia sulfate tank

Mixed documents from almost three decades on the light oil facility, going as far back as the 1930s. These are the oldest documents I have been able to secure.

Mixed documents on the facilities to remove and dispose of this toxic COG component

Pilot program put together at no charge by Wilputte

30 pages of handwritten notes and other printed procedures for shut down/start up/purging of various parts of the BP plant

Correspondence related to the removal of some old unused propane vessels

1994 plan requiring $2 million to upgrade outdated components of the by product plant

1997 control procedures for BP plant components

1995 reports – with ASCII art!

Procedures for clearing alarms in BP plant

1980 in-house inspection of final cooler condition

In-house inspection of COG main feeding the furnace plant

Folder containing mixed flushing liquor related documents

Very old folder of mixed BP component documents

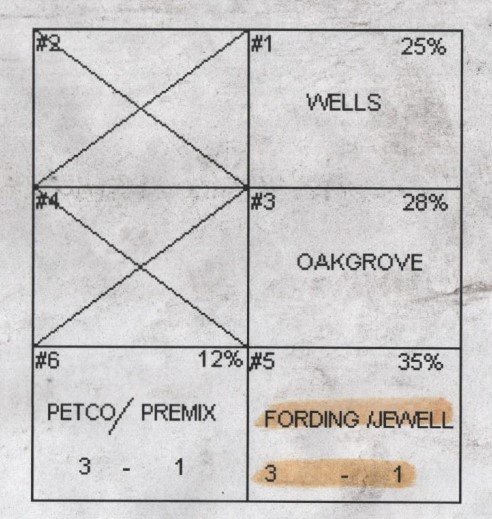

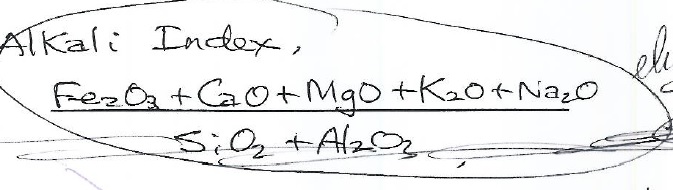

Analysis of by products and incoming coal

BP Plant lab work logs

Coal and coke analysis, light oil shipments and more

Written procedure for incidents (spills, etc) in BP plant, includes three maps

Detailed text on BP processing for weak liquor, includes five blueprints

1998 proposal for an array of new chemicals to be used in BP Plant

Testing done by Wilputte

Proposal/plan for addition to BP plant in 1969

Paint specification for various BP vessels

Coal Handling Documents

Checklists found in the coal handling office

Assessment of department supervisor staffing levels by a consultant and rebuttals

Aerial inspection of CCH department to determine inventory levels

1968 analysis of some of the processes in CCH and how they can improve.

Proposal for a Utah based company to lease the coal handling area at the plant and run it themselves (for a cost). Probably a cost saving idea that never made it past a few meetings.

More coal handling dept docs related to Acme’s non-metallurgical coke

Extremely old monthly reports detailing coal quality

1998 agreement between Acme and a vendor who would unload and store coal until it was needed

Personnel files

These documents tracked employee hours, presumably were sent to payroll

1999 authorization for new job position in ovens department

Excellent documentation that covers the basic responsibilities of the main positions in the oven department

1995 bids for positions

Regular memos that covered personnel changes (new hires, terminations, etc)

Log sheets to prove attendance at mandated safety training (SSCs redacted)

Work schedules showing who was working which shift (oven departments)

Labor hours by position, ovens department

Absentee and accident reports for the coke plant, furnace plant and mill

Complaints against management lodged by the union

Manpower/OT reports for all departments across the entire plant.

Blueprints/Drawings

Large prints (36″ x 36″ or larger)

All large format scanning done by Accurate Repro

1997 drawings by Harding Lawson Associates. Both drawings are excellent references for structure/vessel identification (both are very similar)

Map of entire property and building/vessel arrangement (partially faded)

1985 drawing by Dravo Still (see related report and original manual)

1956 design by Wilputte

1955 design by Wilputte

1969 in-house design

1993 inspection by Orbital Engineering

1996 in-house design

1997 – Orbital Engineering (see related report)

1954 design by Wilputte

1955 design by Wilputte

1990 proposal to outsource CCH by Savage Industries Inc. (see related proposal)

1969 in-house design (see related report, soliciting bids)

1954 design by Wilputte

1957 design by Wilputte

1963 (or 1983?), designed in-house

1968, designed in house

1926, designer unknown.

Wilputte, 1950

Wilputte, 1958

Resorcon Inc, 1990

In House, 1960

Enspect, 2001

In house, 1990

In house, 1990

“Small” format prints (18″ x 12″ or smaller)

These prints were spread across three pages each, I stitched them back together digitally. The quality is not great. But not because of their age, they were clearly photocopied many times before.

Two prints

Five drawings – see associated report

Three prints. Two by Enspect (2000, see associated report) and one by Wilputte (hard to read date)

Wilputte, date hard to read (this is a reduction of a larger print)

Six prints, all done in-house. 1976

Two prints, in-house, 1981

Two prints, in-house, 1981

Two prints, in-house, 1981

Five prints, by Dravo Still (see associated report)

One print, by Orbital Engineering, 1998 (see associated report)

Technical documents

A presentation given by Dr. Charles Lin and Jack Garzella at the 68th Steelmaking Conference, Detroit Michigan, April 1985. The addendum (discovered months later) consists of the original color Polaroid’s (they are Xerox copied in the first copy of the report) as well as an appendix

A paper by Dr. Lin describing the coal blend used by Acme to prevent damage to the ovens through excessive expansion. I found only the long hand rough drafts of this report, then months later the final, typed version.

Five page paper written by Vic Beaucaire early in the days of Acme’s petrography lab

Massive report by Dr. Lin from 1975.

Acme did not have a petrography lab until around 1979. This is a curated number of documents regarding the proposal to have Acme make the investment to build one (they were successful).

A half hearted proposal to use ceramic balls and coke breeze to preheat coal before it is charged into the battery (presumably to decrease coking time). The title references dry quenching, but that is not discussed here, only referenced in the introduction.

Proposal to switch chemical vendors.

1977 rough draft (untyped) collaboration between Vic Beaucaire and Dr. Lin

A presentation given by Doug Podgorny to the American Blast Furnace Association sometime in the early 90s.

1966 report on moisture levels for Illinois coal.

Root cause analysis of an issue at the furnace plant. The photos seen here are actually taped to the hand written pages (regretfully, a few are missing).

Misc.

Material Safety Data Sheets for various coke plant substances

Operator checklist for other machinery

Various documents related to the local shortline railroads the coke plant used and worked with

Manual explaining the implementation of the companies Total Quality Improvement Process

1994 speech from then CEO Steve Bennett touting the new continuous caster and hot strip mill in Riverdale

Nearly 10 years of checklists covering almost the entire 1990s, for BP and Ovens

Internal company newsletter distributed at the Riverdale mill

Before the dawn of email, these mostly intracompany communications cover a number of topics

Additional documents

In early 1997, the coke plant absorbed a large number of employees from the nearby steel mill

Permits and citations

In 1995, the plant sought bids from video production companies to produce an employee orientation video for the oven department

All documents related to the 2001 bankruptcy and attempted sale to WCI